Patents

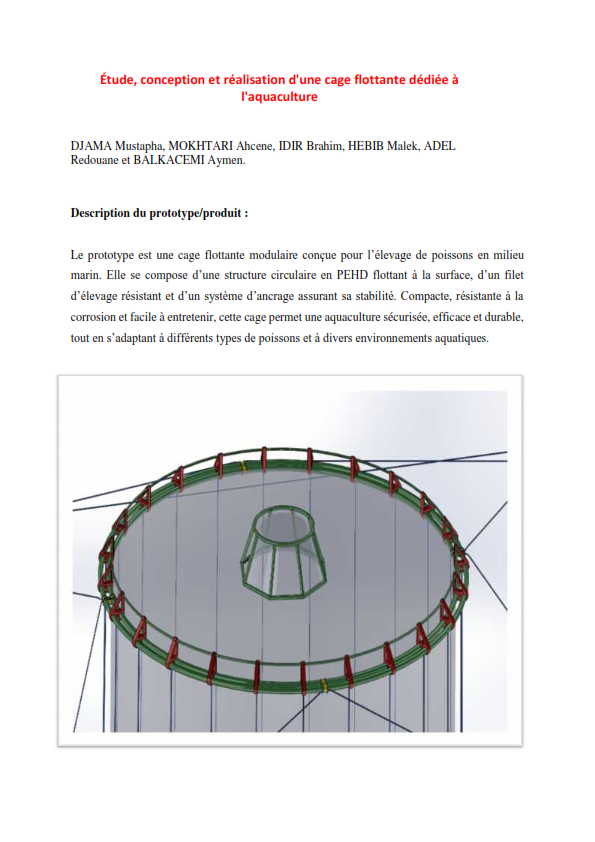

DJAMA Mustapha, MOKHTARI Ahcene, IDIR Brahim, HEBIB Malek, ADEL Redouane et BALKACEMI Aymen.

Le prototype est une cage flottante modulaire conçue pour l’élevage de poissons en milieu marin. Elle se compose d’une structure circulaire en PEHD flottant à la surface, d’un filet d’élevage résistant et d’un système d’ancrage assurant sa stabilité. Compacte, résistante à la corrosion et facile à entretenir, cette cage permet une aquaculture sécurisée, efficace et durable, tout en s’adaptant à différents types de poissons et à divers environnements aquatiques.

Réalisation d'une batterie solaire au plomb-acide avec un agent de pompage d'électrolyte par électro-osmose

HAMIDOUCHE Mohamed, ANNANA Aissam, KENZOUR Abdelghani, MERABTI Halim, MAYOUF Fateh, MAAROUF Tariq et AGHROUT Rachid

Cette batterie stationnaire au plomb-acide, d'une tension nominale de 12 volts et d'une capacité de 150 ampères-heures, est conçue pour stocker l'énergie électrique produite par des installations photovoltaïques, des éoliennes, ou tout autre système de conversion d'énergie renouvelable en électricité.

BADJI Riad, MOKHTARI Ahcene et HADJI Idir

Cette machine concerne un système de ramassage d'objets tels que des pierres couchées ou enfoncées dans le sol. La machine comprenant un châssis, un moyens de séparateur des pierres qui est monté de manière détachable au milieu du châssis, pour agiter le sol et amener le sol pierreux à se déplacer vers des moyens collecteurs et séparer les pierres du sol et déplacer les pierres vers le moyen de transfert, monté sur la machine pour recevoir des pierres provenant du moyen séparateur et transférer les pierres vers le moyen de remorque à benne basculante, puis transporter les pierres jusqu’à un emplacement de déchargement. Des moyens de distribution d’énergie hydraulique pour connecter hydrauliquement l'alimentation d'énergie hydraulique au moyen de remorque à benne basculante ; des moyens de distribution d’énergie mécanique pour connecter mécaniquement l'alimentation d'énergie mécanique au moyen de réparateur.

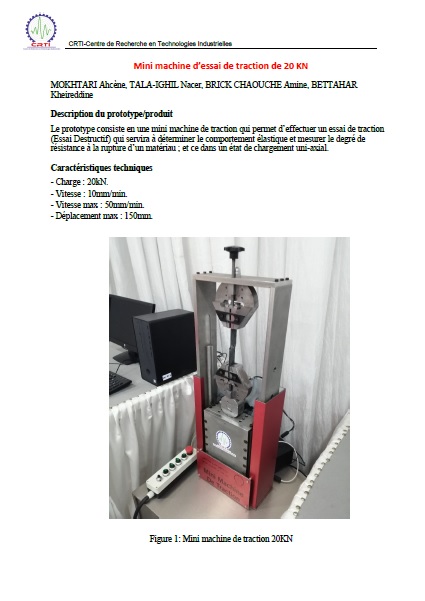

MOKHTARI Ahcene, TALA-IGHIL Nacer, BRICK CHAOUCHE Amine, BETTAHAR Kheireddine

Le prototype consiste en une mini machine de traction qui permet d’effectuer un essai de traction (Essai Destructif) qui servira à déterminer le comportement élastique et mesurer le degré de résistance à la rupture d’un matériau ; et ce dans un état de chargement uni-axial.

BENAMMAR Abdessalem, GUEDJAL Saleh

La machine d’impression 3D industrielle multi-têtes rapide permet de fabriquer des pièces détachées, des objets usuels ou encore des prototypes. Les principaux paramètres de fabrication de ces pièces sont la création ou la récupération d’un modèle 3D c’est-à-dire la définition du modèle à imprimer. L’étape suivante est le tranchage du fichier STL et exportation en G-Code : c’est la phase de transformation du modèle choisi en une donnée exploitable par notre système. Ensuite vient la transmission vers la carte électronique de la machine en utilisant une carte SD ou un câble USB relié à l’ordinateur. Enfin, l’impression 3D est lancée.

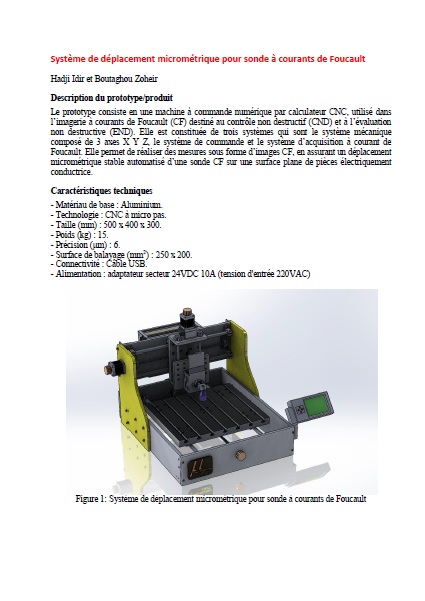

HADJI Idir, Boutaghou Zoheir

This prototype concerns a CNC machine, used in eddy current (CF) imaging for non-destructive testing (NDT) and non-destructive evaluation (NDE). It consists of three systems that are the mechanical system. It is composed of 3 axes (X, Y and Z), the control system and the eddy current acquisition system. It allows to take measurements in the form of CF images, by ensuring an automated stable micrometric displacement of a CF probe on a flat surface of electrically conductive parts.

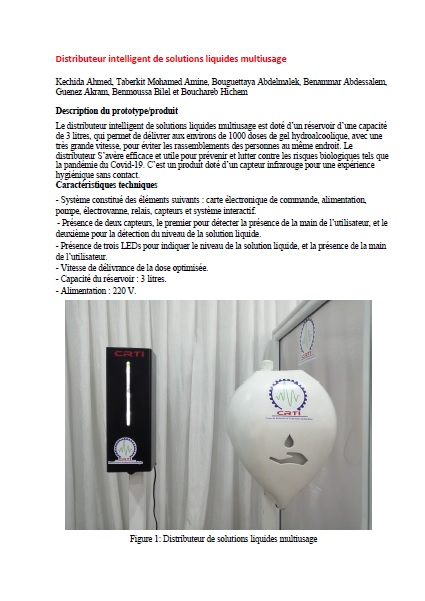

KECHIDA Ahmed, Taberkit Mohamed Amine, Bouguettaya Abdelmalek, Benammar Abdessalem, Guenez Akram, Benmoussa Bilel et Bouchareb Hichem

Le but de l’invention est de réaliser un distributeur de solutions liquides multiusage, doté d’un réservoir d’une capacité de 3 litres, qui permet de délivrer aux environs de 1000 doses, avec une très grande vitesse, pour éviter les rassemblements des personnes au même endroit. Le distributeur pourra être très efficace et très utile pour prévenir et lutter contre les risques biologiques tels que la pandémie du Covid-19, en aidant à adopter les principales et les plus importants gestes barrières. C’est un produit automatique doté d’un capteur à ultrasons pour une expérience hygiénique sans contact. Il se fixe au mur et dispose d’un support mobile également, qui permet de le déplacer facilement entre les différentes parties d’un immeuble. Il est doté également d’un système de détection de niveau du liquide pour ne pas user la pompe du distributeur, ainsi qu’un système de vidage manuel pour une meilleure flexibilité et aisance d’utilisation.

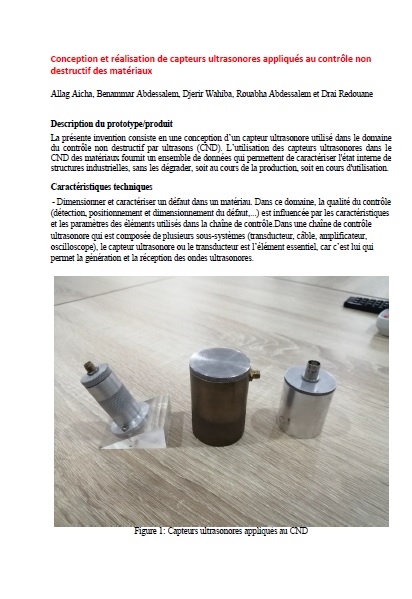

ALLAG Aicha, Benammar Abdessalem, Djerir Wahiba, Rouabha Abdessalem et Drai Redouane

The present invention is related to designing an ultrasonic sensor used in the field of ultrasonic non-destructive testing (NDT).

The use of sensors in the NDT of materials provides a set of data, which allows characterizing the internal state of industrial structures, without degrading them, either during the production process or in use.

The choice of sensor is important for non-destructive evaluation of materials. Generally, the sensor is characterized from the electrical point of view by: the resonant frequency, the quality factor and the bandwidth at -3 dB. From the acoustic point of view, it is also characterized by the distribution of the acoustic pressure generated in the material to be controlled. The characteristics of each sensor may be different depending on the field of application.

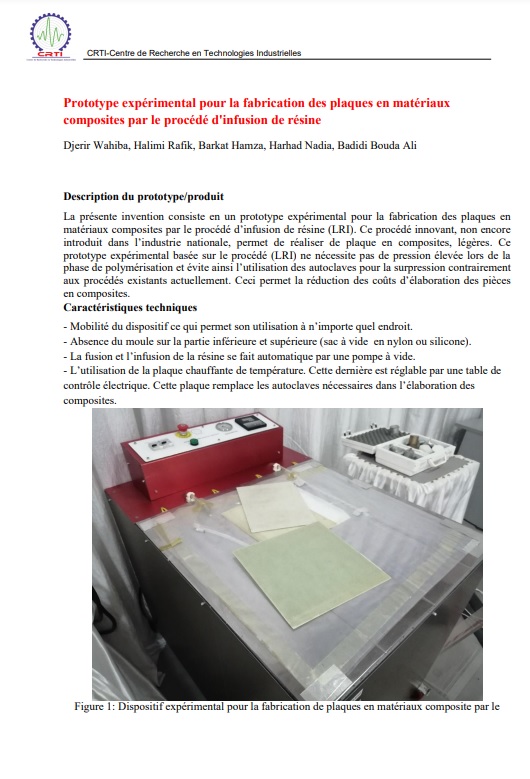

Experimental prototype for the manufacture of composite material plates by the Liquid resin infusion process (2020)

DJERIR Wahiba, HALIMI Rafik, BARKAT Hamza, HARHAD Nadia & BADIDI BOUDA Ali

The aim of the invention is to produce a mobile experimental prototype for the manufacture of composite material plates by the Liquid Resin Infusion process (LRI). This process, which has not yet been introduced in the national industry, makes it possible to produce lightweight composite plates with good mechanical properties. The standard fiber volume ratio of the composites produced by this infusion process is 55%. In this device, the use of the adjustable temperature hotplate replaces the autoclaves necessary in the production of composites. In addition, because of the absence of mold on the upper part (nylon or silicone vacuum bag) and the reuse of the lower mold, this process allows producing composite parts at a lower cost under flexible conditions. Our novelty is based on:

- Mobility of the device which allows its use on site.

- Absence of the mold on the upper part (nylon or silicone vacuum bag).

- Infusion of the resin is done automatically by a vacuum pump.

- Use of the adjustable temperature heating plate by an electric control table. This hot plate replaces the autoclaves required in the production of composites.

.jpg)

AISSANI Mouloud, Nabil KARECHE, Raouf BEL RACHID, Mustapha LAIDOUNE, Nacer TALA-IGHIL, Riad BADJI, Mostepha YAHI

The invention is related to a friction stir welding machine (Friction Stir Welding) of a portal type with 4 degrees of freedom. It allows to carry out complex assembly process by FSW. It consists of three essential parts: a Base, a Portal and a Tool holder. This machine is intended for the permanent assembly of parts made of heterogeneous materials or parts that are difficult to weld using standard methods (as fusion welding). The machine carries a very sophisticated tool, which is kept in contact with the two parts to be assembled thanks to a significant forging force provided by the Gantry. The tool under pressure and in rotation on the surfaces to be welded, generates by friction, the heat necessary for penetration into the material which is in a pasty state. The tool moving in translation along the weld joint mixes the material from the two materials to be joined, which allows obtaining a quality weld bead. This invention, with a direct and immediate impact on the industry, will essentially serve to introduce and popularize the innovative technique of assembly by the FSW process in the national industrial sector.

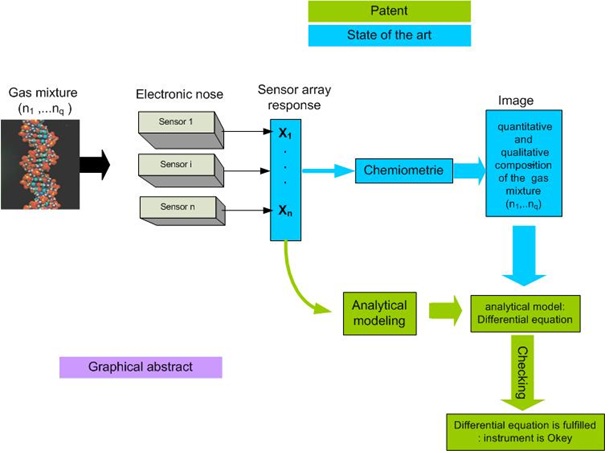

ABBAS Abdelaziz, A. Bouabdallah

Chemical gas multi-sensors (or electronic nose) are electronic devices that can be used to detect gas particles, analyse gas mixtures and identify odours. Like all electronic instruments, they are subject to drifts and need often to be calibrated in order to avoid false measurements. In previous published papers, we suggest novel analytical models that describe the steady state interactions between an electronic nose and a mixture of vapours. They relate the variations of the sensors partial sensibilities to gas mixture components concentrations. The deduced models can be used to verify the consistency of experimental sensor array data and so to test the efficiency of the sensor array elements.

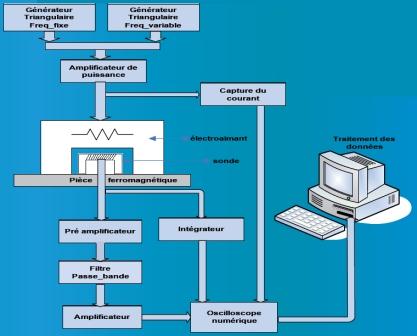

Mourad ZERGOUG, Omar BOURDJAM & Abdessalam ROUABHA

The objective of this patent is to produce a Barkhausen noise generation and acquisition device to detect defects that may contain a material and to trace the hysteresis cycle in order to determine the magnetic properties of ferromagnetic materials. This determination will allows to assess the microstructure of materials from calculated electrical and magnetic data.

.jpg)

ABEDGHARS Mohamed Tayeb, BENCHIHEB Omar

Cette invention concerne un procédé d’élaboration de la poudre de fer par réduction indirecte d’un sous produit sidérurgique qui est la calamine en utilisant un gaz réducteur. Ce gaz est composé essentiellement de monoxyde de carbone. Le produit obtenu est une poudre de fer avec un taux très élevé de métallisation.

AISSANI Mouloud, Saliha Gachi

L’invention concerne une machine de soudage par friction malaxage (Friction Stir

Weldingd e type portique à 4 degrés de liberté. Elle permet de réaliser le procédé complexe

d’assemblage par FSW. Elle est constituée de trois parties essentielles : une Base, un

Portique et un Porte-outil. Cette machine est destinée à l’assemblage permanant des pièces

de matériaux hétérogènes ou difficilement soudables par les méthodes standards (exemple

soudage par fusion).

La machine porte un outil très perfectionné qui est maintenu en contact avec les deux pièces

à assembler grâce à une force de forgeage importante fournis par le Portique. L’outil sous

pression et en mouvement de rotation sur les surfaces à souder, génère par frottement, la

chaleur nécessaire à la pénétration dans la matière qui se trouve dans un état pâteux. L’outil

en mouvement de translation le long du joint de soudure assure le malaxage de la matière

issue des deux matériaux à assembler, ce qui permet d’obtenir un cordon de soudure de

qualité. Cette invention à impact direct et immédiat sur l’industrie, servira essentiellement à

introduire et à vulgariser la technique novatrice d’assemblage par le procédé FSW dans le

secteur industriel national.